In the fast-paced logistics industry, success hinges on on-time deliveries, cost efficiency, and real-time visibility. However, many companies struggle with outdated manual processes, disconnected systems, and unpredictable delays, which lead to dissatisfied customers and reduced profits.

Fortunately, Microsoft Dynamics 365 Supply Chain Management (D365 SCM) offers a solution by empowering logistics providers with AI-driven route optimization, real-time tracking, and automated workflows. This technology can help companies reduce delivery delays by up to 40% and cut fuel and labor costs by 15-20%, while also improving customer satisfaction with end-to-end shipment visibility.

As a Microsoft Solutions Partner, Cambay Solutions specializes in helping logistics companies transform their operations with Dynamics 365.

Overcoming Key Challenges in Logistics

Before implementing solutions, it’s important to understand the common challenges that logistics companies face. Inefficient route planning often results from manual scheduling, which leads to longer transit times and higher fuel costs. The lack of real-time data on traffic and weather can also cause unexpected delays.

Another major issue is poor visibility across the supply chain. Disconnected systems like TMS, WMS, and ERP create blind spots in shipment tracking, making it difficult to provide customers with the real-time ETAs they demand. Additionally, rising operational costs are a constant concern, driven by empty backhauls, inefficient load planning, and time-consuming manual paperwork.

Finally, compliance and documentation risks are a significant burden, as manual processing of bills of lading (BOL) can lead to errors and fines, and the lack of automated audit trails complicates regulatory compliance.

How Dynamics 365 Provides Solutions

Dynamics 365 addresses these challenges directly. Its AI – powered route optimization engine analyzes traffic, weather, and vehicle capacity to recommend the fastest and most cost-effective routes. Through machine learning, the system improves its accuracy over time by learning from past deliveries. For example, one US trucking company reduced its fuel costs by 18% using D365’s dynamic routing.

The platform also enables real-time shipment tracking through IoT-enabled GPS, providing live updates on driver location and delays. Customer portals can display real-time ETAs, which helps reduce inbound queries by an average of 35%. According to Deloitte, 89% of shippers consider real-time tracking to be critical.

![]()

Furthermore, Dynamics 365 offers automated load and fleet management with smart algorithms that optimize truck space and predictive maintenance alerts that can reduce vehicle downtime by 25%. For paperless logistics, AI can scan and digitize bills of lading, packing slips, and invoices, while blockchain-secured records ensure tamper-proof compliance logs.

Implementing Dynamics 365 for Optimal Performance

The implementation process for D365 begins with an assessment of current workflows to identify bottlenecks, such as manual dispatch or outdated TMS, and to define key performance indicators (KPIs) like on-time delivery percentage and fuel costs. The next step involves deploying D365 SCM modules, including Transportation Management to automate route planning and Warehouse Management to synchronize inventory with delivery schedules. An IoT Hub can also be integrated to connect telematics for real-time fleet tracking. The third step is to integrate with existing systems using tools like Azure Logic Apps to connect D365 with ERP, EDI, and customer CRM systems.

Finally, training teams and monitoring ROI is crucial, with role-based training for all staff and continuous tracking of delivery performance, cost savings, and customer feedback.

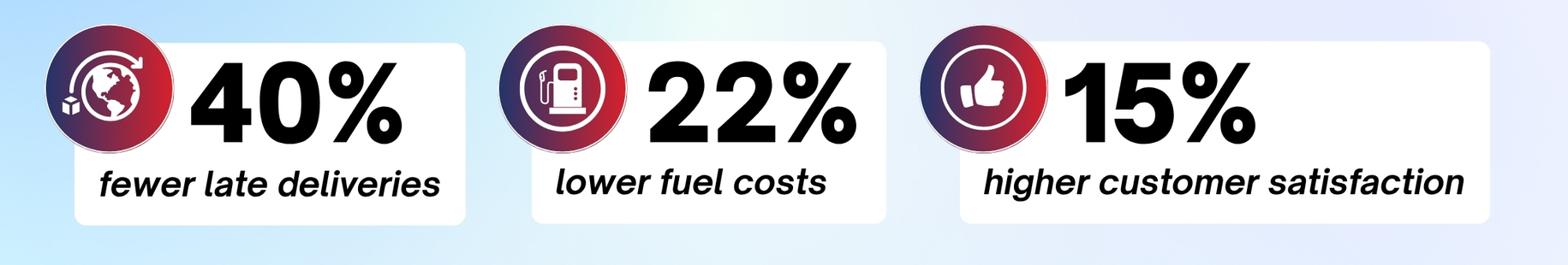

A mid-sized 3PL provider, for instance, was struggling with a 30% rate of delayed deliveries and rising fuel costs. Cambay Solutions implemented D365 SCM with AI route optimization, IoT-enabled fleet tracking, and automated freight billing. As a result, the client achieved a 40% reduction in late deliveries, a 22% decrease in fuel costs, and a 15% increase in customer satisfaction.

Cambay Solutions, as a Microsoft Solutions Partner, specializes in providing tailored D365 logistics configurations and seamless integration with Azure AI, Power BI, and legacy systems. We offer end-to-end support, from initial deployment to staff training, to ensure a smooth transition and successful outcome.